FEBRUARY 2022 | Chairman’s Message

March 11 — World Plumbing Day — is fast approaching, and once again we will celebrate across the world the contributions of the plumbing industry toward the health and safety of our planet. Every year plumbing is getting more and more respected as an essential profession that contributes to the well-being of our economies. Here in the United States, we have neglected investment in infrastructure, causing many disruptions in our drinking water and sanitation. Many of us take this for granted every day until something breaks.

March 11 — World Plumbing Day — is fast approaching, and once again we will celebrate across the world the contributions of the plumbing industry toward the health and safety of our planet. Every year plumbing is getting more and more respected as an essential profession that contributes to the well-being of our economies. Here in the United States, we have neglected investment in infrastructure, causing many disruptions in our drinking water and sanitation. Many of us take this for granted every day until something breaks.

Fortunately, our president recognizes that we as a country are at a critical point when it comes to our infrastructure. One of the main topics of his infrastructure investment is the removal of lead piping in our water systems. Most plumbers know that the name plumber derives from the Latin word plumbum, which means “lead” on the periodic table. Lead was the material used for the early systems of the Roman Empire. Some historians suggest that the reason for the decline of the Roman Empire was too much lead in the drinking water. It’s funny how history continues to repeat itself, but with a $15 billion to $30 billion investment, we are on a path to removing all lead lines throughout the country and providing good-paying jobs for plumbers.

The WPC is still on hold regarding educational scholarships. We will discuss this at our upcoming virtual executive board meeting. The world is not quite ready yet to open all borders for travel. The WPC scholarships have been our greatest achievement and we want everyone to experience the sharing of educational knowledge in the safest manner possible. We are monitoring the situation and will make our announcements as soon as possible. Speaking of training, the organization for which I work, the United Association of Plumbers and Pipefitters, holds an annual training seminar in Ann Arbor, Michigan, that brings together more than 2,000 instructors from all over the United States and Canada to be trained in the best methods of teaching plumbing, HVAC, welding and CAD, just to mention a few. We also host an apprentice contest that brings the most talented apprentices from more than 50,000 apprentices from Canada, the USA and Australia. The UA has sponsored a winner form the WPC scholarship fund to attend this event as well. We look forward to hosting another winner from the WPC soon.

I was hoping that I wouldn’t have to mention the pandemic in this newsletter, but it seems like it won’t be going away anytime soon. The world is growing frustrated with mask mandates, and protests and disruptions are becoming the norm as we all struggle to get back to normal. Energy prices have continued to rise, and raw material shortages has caused long delays in construction and manufacturing. The most pressing issue facing the world today is a possible war in Ukraine. Our prayers go out to all world leaders to come to some agreement that will avert any more senseless wars.

In closing, I hope everyone in the plumbing community is safe and has a prosperous New Year. Don’t forget to send in your World Plumbing Day celebration stories and photos so we can post on our website.

WPC Chairman

Tom Bigley

IN THIS ISSUE:

An Optimized Sanitary Stack Configuration for Mid-Rise Multifamily Construction

Registration Open, Schedule Released for Seventh Emerging Water Technology Symposium

IWSH Sponsors Poster Contest for 13th Annual World Plumbing Day

Donations of Gift Cards for Reach Unlimited in Cypress this Christmas

NITC Suppports the WPC’s Objective To Create a Global Network

No More Waste: Plumbing Industry Launches PVC Recycling Scheme

New Zealand Institute of Central Heating Partners with BPEC to Raise Standards

An Optimized Sanitary Stack Configuration for Mid-Rise Multifamily Construction

Submitted by John Lansing, CPD, LEED Green Associate, is a Certified Plumbing Designer

Republished with permission from ASPE Pipeline

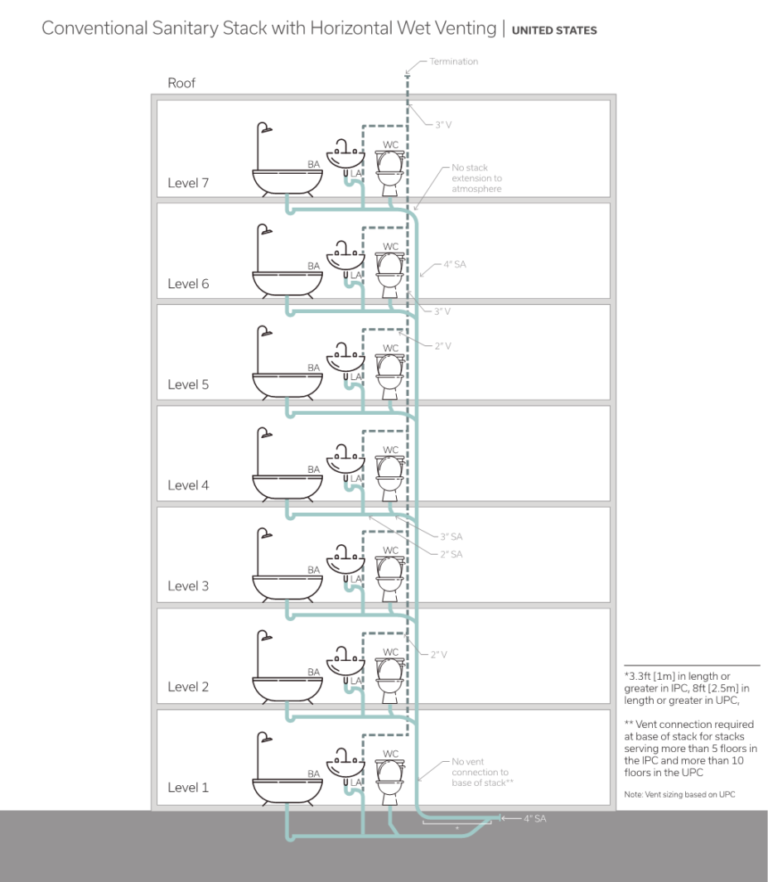

The design practices surrounding American sanitary drainage and vent systems closely reflect those in plumbing codes published in the first half of the 20th century. While venting methods such as circuit venting and horizontal wet venting were more recently introduced in some areas of the country, these configurations can be found in the National Bureau of Standards (NBS) publications, which are essentially the framework for the International Plumbing Code (IPC) and Uniform Plumbing Code (UPC®).

As building drainage theory progressed in the second half of the 20th century, mostly led by the Building Research Station (BRS) and Heriot-Watt University in the United Kingdom, drainage design in American plumbing codes remained mostly the same. This is prominently demonstrated by the emphasis on fixture vent piping over the venting of sanitary stacks, particularly for stacks serving fixtures in mid-rise buildings without auxiliary vent stacks. A majority of national standards utilize stack venting as a primary means of venting fixtures, a concept more familiar to those in the U.S. as the Philadelphia stack or the single-stack vent system, which can be found in Chapter 9 of the IPC and Appendix C of the UPC.

The following discussion will focus on the development and varying requirements of the single-stack vent system and proposals for modifications to the American variation to increase the functionality of this method in mid-rise multifamily construction.

History

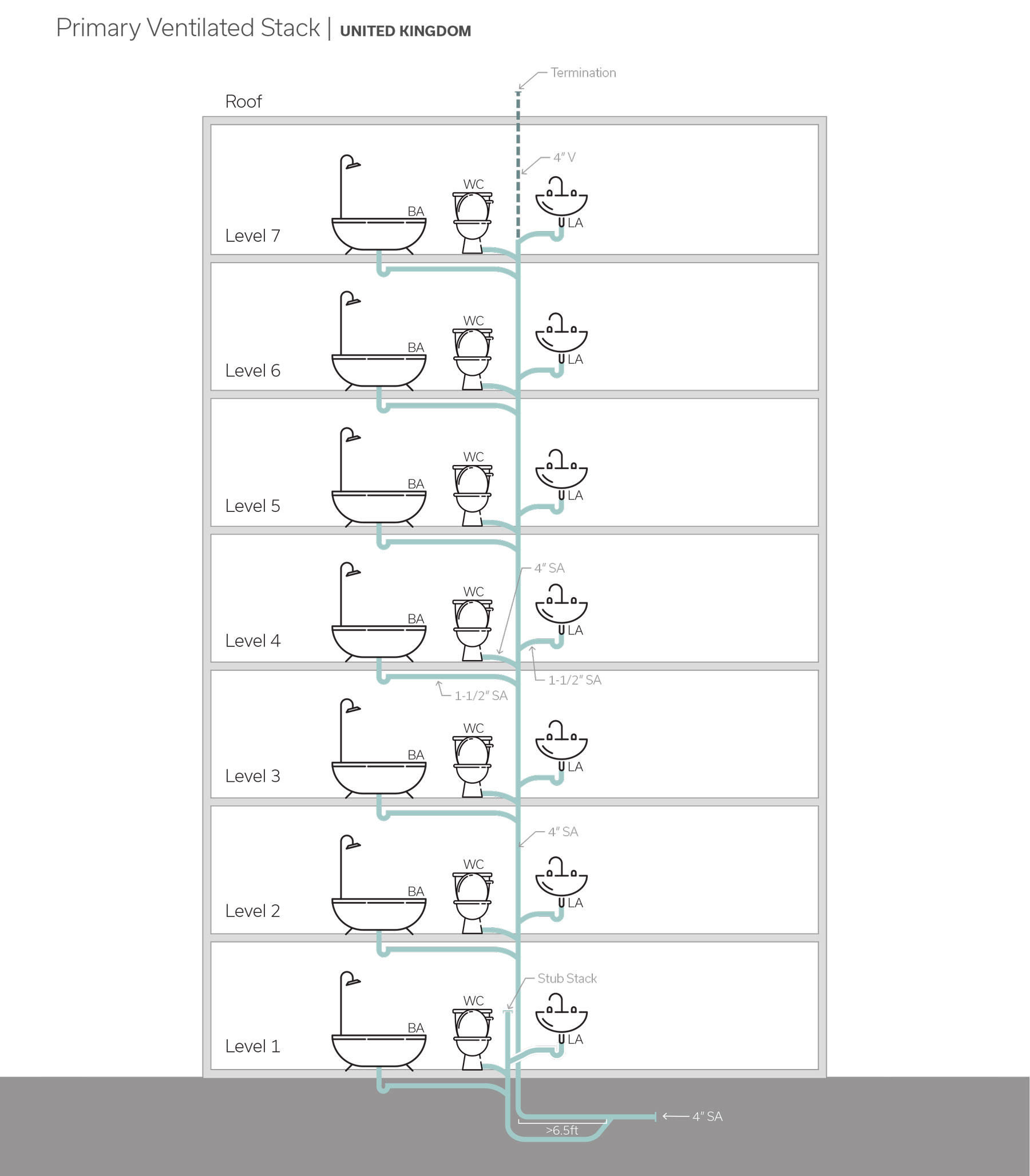

After the end of World War II, the UK launched efforts to rebuild the hundreds of thousands of homes that were destroyed, seeking new strategies to optimize labor and resources. This led Alfred Wise of the BRS to investigate a simplified approach to sanitary drainage stacks. With extensive experimental testing, Wise developed a drainage configuration that allowed the elimination of individual fixture vents, also known as anti-siphon vents, relying instead on the free passage of air through the top of the drainage stack to limit negative pressure development to protect the water seals in fixture traps. Wise found that if the length of the horizontal drain between the fixture trap and stack connection was limited, the stack configuration was suitable for serving up to 10 floors of fixtures (see Figure 1).

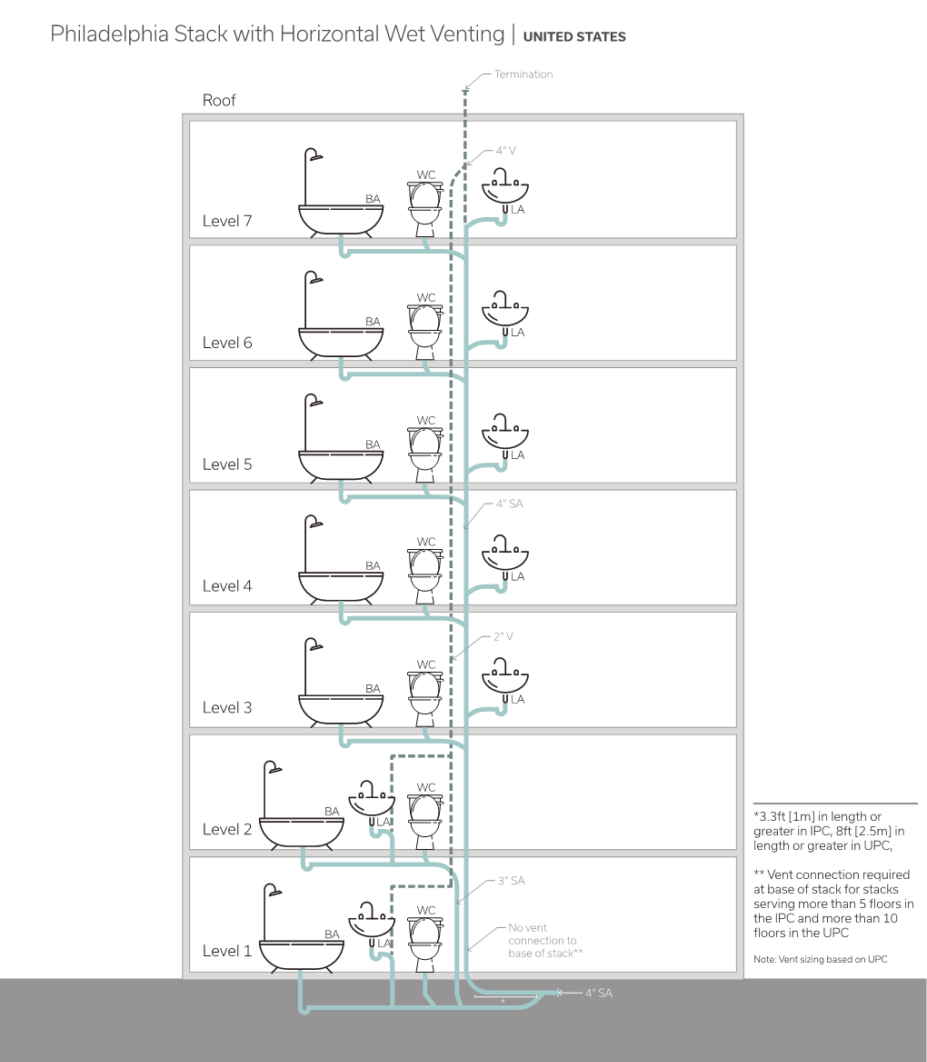

Variations of Wise’s single-stack configuration quickly spread throughout Europe, Asia, Latin America, Africa and Oceana. Wise’s reports seem to indicate that he was unaware that a nearly identical configuration was already in use in Philadelphia. This American variation was initially developed by Boston architect J. Pickering Putnam and introduced at the 1911 American Institute of Architects (AIA) convention in San Francisco. Sometime after the development of the fixture unit method, a load sizing table was introduced for the Philadelphia stack configuration, along with stack height limits for each stack diameter. The Philadelphia stack was further developed by the American Society of Plumbing Engineers (ASPE) and eventually was featured in the appendix of the UPC in 2006 and Chapter 9 of the IPC in 2012 (see Figure 2).

Despite being used in Philadelphia for more than a century and being listed as an approved method in the IPC, the single-stack configuration has failed to gain widespread use in the U.S., likely due to some key design limitations.

Fundamental Design Requirements

Design requirements for the single stack vary in each country, along with the name of the configuration itself, with China and Japan describing the method as extension ventilation and Europe using the term primary ventilation. One common principle shared by almost all national variations is that the single stack allows the elimination of all vent piping anywhere along the stack or serving the fixtures connecting to the stack, with the one exception being the top of the stack itself, extending beyond the top fixture connection full size and terminating to the atmosphere. Most national and regional standards, with some exceptions, have a maximum allowable pressure differential of 1 inch (25 mm) of water column at fixture traps, allowing the performance between drainage systems to be more easily compared.

Fixtures on the Lowest Floor

The pressure surge problems associated with fixtures connecting directly above or downstream of a stack are almost universally recognized in plumbing codes and design guides. Most standards require fixtures on the lowest floor to connect downstream of the stack at a specified minimum distance and avoid connecting to the lowest floor above the stack base unless the lowest floor connection can be made above 2.5 to 8 feet (0.75 m to 2.5 m) or so above the stack base. Standards in Germany and China suggest providing a vent from the lowest floor fixtures and terminating this vent into the sanitary stack with a wye fitting at the same floor. In the UK, fixtures on the lowest floors connect into a stub stack, which is essentially a capped stack roughly 6 feet (2 m) in height. The stub stack connects horizontally downstream of the stack, relying on the airflow within the upper portion of the horizontal piping to alleviate pressure differentials.

The Philadelphia stack, however, requires separating out the two lowest floors for stacks greater than three floors in height. The stack serving the lower two floors may also use the Philadelphia configuration or may use another venting option, such as horizontal wet venting, both of which require extending a vent running from the lowest floor to an atmospheric termination point. Providing vent piping along the entire stack length undermines the advantages of the configuration over the typical horizontal wet vent stack (see Figure 3) and is unnecessary in this application for the protection of water seals.

Height Limitations

As drainage stacks increase in height, the amount of airflow required to alleviate negative pressure from drainage increases. Depending on the design standard, the single stack is limited to a maximum of 10 to 20 floors to avoid airflows that would cause water seals in traps to fail. Once a stack height is considered too great, most design standards recommend providing an auxiliary vent stack connecting above the sanitary stack base, along with intermediate relief connections along the length of the stack. This configuration, widely known as the secondary ventilated stack, still allows fixtures to connect into the stack without a vent connection between the trap and stack connection.

For the 4-inch stack, a typical size for stacks serving bathrooms in most countries, the Philadelphia configuration is effectively limited to 75 feet (23 m)*, a height equivalent to about seven or eight floors. This height may be exceeded by increasing the stack diameter by one size. The 5-inch stack, typically considered a special-order size, is limited to 160 feet (49 m). The IPC also requires an auxiliary vent stack for the single-stack system if the height exceeds more than five floors, though this is a standard requirement for all sanitary stacks in the IPC and it may have been the intention to add the single stack to the list of exempted configurations.

Horizontal Distance from Stack Limitations

To avoid issues of self-siphonage, design standards limit horizontal drainage branch lengths between the trap and the branch connection to the stack. In Europe, this is generally limited to somewhere between 13 feet (4 m) and 33 feet (10 m). The UK has no limits for water closets or bathtubs but limits lavatories to a maximum of 10 feet (3 m). For the Philadelphia variation, water closets may be up to 8 feet (2.5 m) from the stack, while other fixtures may be up to 12 feet (3.7 m). Most configurations, including the Philadelphia stack, allow an S trap from the lavatory, though the Philadelphia stack requires increasing the fixture drain from a 1½-inch drain to a 2-inch drain prior to transitioning vertically to provide additional protection against self-siphonage.

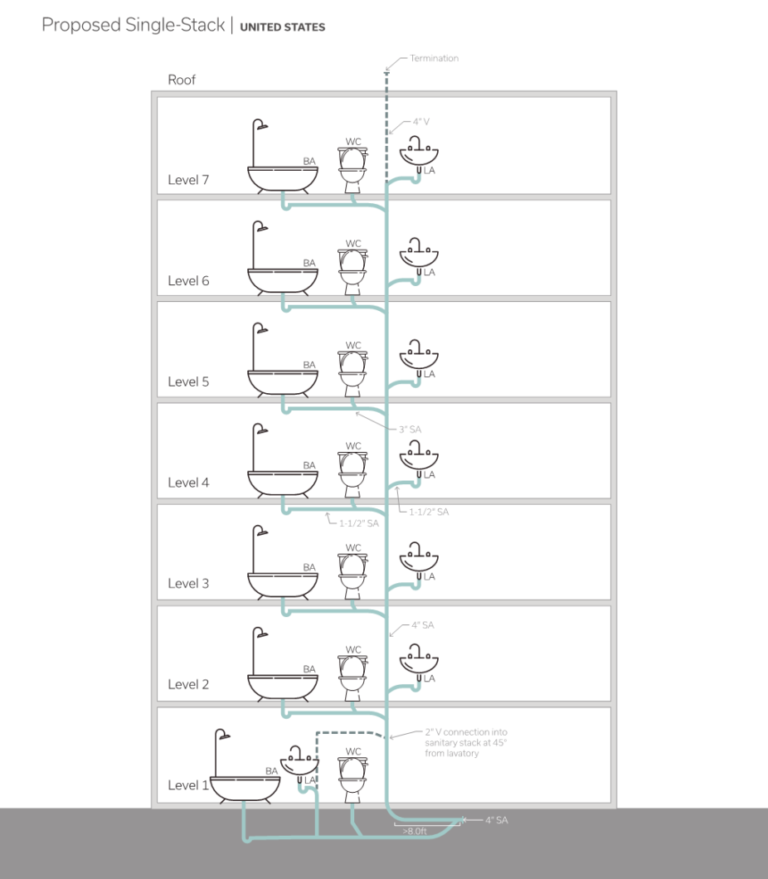

Proposed Modifications to the Single Stack

Thanks to a research grant provided by ASPE’s Portland Chapter and assistance from Dr. Michael Gormley of Heriot-Watt University, a new variation of the single stack is being proposed in the upcoming 2024 UPC. This variation addresses the issues with the impractical venting requirements of the Philadelphia stack for fixtures on the lower floors by utilizing the approach used in Germany and China (see Figure 4). The proposal also only requires separating the first floor from the stack for stacks less than 75 feet (23 m). These minor modifications to the single-stack method will significantly increase the practicality of the configuration, making it a viable alternative to conventional sanitary stacks for mid-rise multifamily construction.

*4-inch stacks greater than 75 feet in height may only be used if the load does not exceed 24 drainage fixture units (DFU), equivalent to six floors of bathrooms.

2021 International Plumbing Code. (2020). Country Club Hills: International Code Council.

2021 Uniform Plumbing Code. (2020). Ontario: International Association of Plumbing and Mechanical Officials.

BS EN 12056-2 – Gravity Drainage systems inside buildings. (2000). British Standards Institute.

Design Manual for Building Water Supply and Drainage. (2019). Beijing: China Architecture Design & Building Press.

DIN 1986-100 Drainage systems on private ground. (2016). German Institute for Standardisation.

Lansing, J. (2020). A Comparison of British and American Plumbing Engineering Standards and Practices. Zurich: World Plumbing Council.

Swaffield, J. (2010). Transient Airflow in Building Drainage Systems. London: Spon Press.

About the Author

John Lansing, CPD, LEED Green Associate, is a Certified Plumbing Designer in Portland, Oregon, working with PAE Consulting Engineers. John was the recipient of the World Plumbing Council’s 2018 Education and Training Scholarship, which gave him the opportunity to author a report on differences between British and American plumbing engineering. He also authored Maintaining Domestic Hot Water Return Temperatures Above the Growth Range of Legionella, published by ASPE. John is passionate about sustainable and regenerative plumbing strategies as well as studying plumbing engineering standards and design guides from other countries.

John Lansing, CPD, LEED Green Associate, is a Certified Plumbing Designer in Portland, Oregon, working with PAE Consulting Engineers. John was the recipient of the World Plumbing Council’s 2018 Education and Training Scholarship, which gave him the opportunity to author a report on differences between British and American plumbing engineering. He also authored Maintaining Domestic Hot Water Return Temperatures Above the Growth Range of Legionella, published by ASPE. John is passionate about sustainable and regenerative plumbing strategies as well as studying plumbing engineering standards and design guides from other countries.

Any opinions expressed in this article are those of the author and not the American Society of Plumbing Engineers.

IWSH Supports Access to Revolutionary Mobile App to Increase Women’s Access to Public Toilets in India

The International Water, Sanitation and Hygiene Foundation (IWSH) is pleased to announce its support for a cause led by Woloo, an Indian startup company whose app aims to ensure women access to clean, safe and hygienic toilets in public places.

The app, which is available on Android devices and is coming soon to IOS, helps women locate the nearest washroom when they are away from their home or office.

Even though women comprise more than 48 percent of the Indian population, lack of access to such facilities remains a problem. Finding a usable toilet in public spaces can be a challenge for women of all socioeconomic backgrounds, particularly those who regularly venture outside of the home. Many of the public toilets that are available were built with limited budgets and are poorly designed and maintained. While approximately 13% of the world’s female population lacks access to toilets, studies have put that number closer to 50% in India.

Each Woloo-enabled washroom follows a standard protocol to ensure safety, cleanliness and hygiene, which is based on a guideline developed by the Toilet Board Coalition, a global nonprofit enterprise, and the Woloo Assurance of Hygiene (WAH) based on safety, hygiene and accessibility parameters. Woloo maintains more than 1,500 washrooms across Mumbai, with plans to expand to Jaipur, Ahmedabad, Pune and Bangalore.

“Woloo’s mission is to provide hygiene dignity to a diverse group of women of all ages in India,” said Woloo founder/CEO Manish Kelshikar. “Our partnership with IWSH and IAPMO will certainly help in raising the standards of shared sanitation in India to world-class benchmarks. IWSH, IAPMO and its partners, and Woloo will work together and build trust in shared and public sanitation.”

IWSH has donated funding for 1,000 annual subscriptions, which will go to women of Mumbai’s Railway police force, and is contributing toward a public relations campaign promoting a new facility in the Ghatkopar Metro station in Mumbai. Ashirvad Pipes, Cera India and A.O. Smith India have generously donated IAPMO-certified products for the project. The 1,000-square-foot Woloo-PowderRoom Lounge will include eight smart toilets, a 14-seat café and a 600-square-foot retail area catering to women’s hygiene, personal care, intimate utility and beauty products. An exclusive preview was held Jan. 30.

IWSH has donated funding for 1,000 annual subscriptions, which will go to women of Mumbai’s Railway police force, and is contributing toward a public relations campaign promoting a new facility in the Ghatkopar Metro station in Mumbai. Ashirvad Pipes, Cera India and A.O. Smith India have generously donated IAPMO-certified products for the project. The 1,000-square-foot Woloo-PowderRoom Lounge will include eight smart toilets, a 14-seat café and a 600-square-foot retail area catering to women’s hygiene, personal care, intimate utility and beauty products. An exclusive preview was held Jan. 30.

The mission of Woloo, which opened its first facility Nov. 19, 2019 — World Toilet Day — is to provide world-class access to hygiene facilities for women of all ages and diversities across India.

“Lack of access to improved sanitation, especially out of the home, for women has remained a difficult problem to solve, leading to immense anxiety on one hand and continuing a high burden of disease on the other,” said Dr. Nimish Shah, managing director of IAPMO India Pvt. Ltd. “There are very few sustainable models that have successfully solved this problem. Woloo is a promising women’s hygiene and sanitation access platform that is taking this challenge head on. IWSH and IAPMO are proud to partner with Woloo in its mission to provide safe, clean and hygienic sanitation access for women. We believe that quality, certified hardware underpins the durability of improved sanitation, and Woloo powder rooms are perfect venues to demonstrate well-designed, hygienic public toilets.”

Visit www.woloo.in to learn more about Woloo India.

Visit www.iwsh.org/iwsh/our-work/asia/in to learn more about IWSH work in India.

Registration Open, Schedule Released for Seventh Emerging Water Technology Symposium

Early-bird registration is now open for the seventh Emerging Water Technology Symposium (EWTS), which returns to being an in-person event May 10-11 in San Antonio. To register, visit https://www.aspe.org/2022-ewts-registration/.

Early-bird registration is now open for the seventh Emerging Water Technology Symposium (EWTS), which returns to being an in-person event May 10-11 in San Antonio. To register, visit https://www.aspe.org/2022-ewts-registration/.

The EWTS is co-convened by the American Society of Plumbing Engineers (ASPE), the Alliance for Water Efficiency (AWE), the International Association of Plumbing and Mechanical Officials (IAPMO) and Plumbing Manufacturers International (PMI), in cooperation with the World Plumbing Council (WPC).

The EWTS will include the following presentations:

- “Non-potable Water Systems: Unique Plumbing Code Considerations” by Phillip White, manager of plumbing and mechanical inspections, City of Vancouver, British Columbia

- “The Role of Safety and Performance Requirements in Reinventing the Toilet” by Sun Gil Kim, program officer for the Bill and Melinda Gates Foundation

- “Direct Potable Reuse — Can It Be a Consumer Product?” by Markus Lenger, Clean Blu Innovation

- “Understanding the Need, Benefits and Limitations of Applying Supplemental Disinfection Control in Plumbing Systems” by Janet E. Stout, president and director, Special Pathogens Laboratory

- “Understanding the Application and Potential of the Water Demand Calculator” by Professor Steve Buchberger, University of Cincinnati

- Panels on “Effective Risk Management of Building Water Systems for Pathogen Control” and “Implications of the Infrastructure Investment and Jobs Act and Build Back Better Legislation on Water Infrastructure and Plumbing”

- And many more!

A complete schedule is available at https://ewts.org/2022-schedule/.

“IAPMO and our fellow co-conveners are very excited to announce that registration for the EWTS is open, as this is our most impressive program to date,” said IAPMO Senior Vice President of Training and Credential Services Tony Marcello. “For the first time in the event’s history, we will be offering a dual track of presentations on Day 2 of the program.”

Dr. Richard Thorsten, chief impact officer for Water.org, and Robert Puente, president and CEO of the San Antonio Water System, will deliver the keynote addresses at the biennial event. The EWTS provides a unique opportunity to meet well-known experts from across the globe. Participants can discover ideas and approaches about emerging technologies coming to market; learn about innovative green plumbing and mechanical concepts; view presentations; and engage in timely discussions on how the water utility, manufacturing, engineering, and trade industries have found solutions through emerging technologies for the water efficiency, plumbing and mechanical industries.

Attendees are advised to register early, as seating is limited. The early-bird rate of $495 ends March 15. Additional information may be found at www.ewts.org.

Presentations and a series of videos from previous symposiums are available for viewing at www.youtube.com/user/IAPMOGroup/playlists.

If you have any questions about the EWTS, please contact Maria Bazan at (708) 995-3000.

IWSH Sponsors Poster Contest for 13th Annual World Plumbing Day

The International Water, Sanitation and Hygiene Foundation (IWSH) invites schoolchildren across the world to participate in its poster contest celebrating the 13th annual World Plumbing Day — March 11.

The international poster contest is open to elementary/primary school students in grades one to six. The winning poster creator will receive USD $100, with USD $1,000 going to his/her school. The second-place prize is USD $50/$500, and third place is USD $25/$250. Select entries will also be featured on IWSH social media channels throughout the month.

The international plumbing community plays a vital role in promoting the link between good quality plumbing, environmental sustainability, economic prosperity, and, even more than ever during the present global COVID-19 pandemic, public health and hygiene. World Plumbing Day is a vital way to remember, highlight and promote that link.

An entry consists of a poster, U.S. letter size or A4 size, made solely by the entrant and inspired by World Plumbing Day. It must feature the wording PLUMBING IS ESSENTIAL. Only one entry per person is permitted.

To enter, submit one poster with the student’s name, grade level, teacher’s name, school name and school address to postercontest@iwsh.org. All entries must be received by March 31.

Entries may also be mailed to: IWSH, 4755 E. Philadelphia St., Ontario, CA 91761, USA. For more information about IWSH’s World Plumbing Day poster contest, visit www.iapmo.org/iwsh/wpd-poster-contest.

Donations of Gift Cards for Reach Unlimited in Cypress this Christmas

Submitted by Dorothy Gurka | Gulf Coast PHCC, Houston, TX, USA

The Gulf Coast PHCC members were very generous in their donation of gift cards to local restaurants for Reach Unlimited in Cypress this Christmas. Reach Unlimited is a non-profit dedicated to providing quality support services for people with intellectual and developmental disabilities. Every card was a favorite place and they are going to share with all of their friends.

Thank you to board member Matt Lindsay with The Lindsay Co. for coordinating the delivery of the gift cards.

A Much-Needed Lesson?

Submitted By Peter McLennan

This article first appeared in the summer 2019 edition of Plumbing Connection Magazine. Their weblink is: www.plumbingconnection.com.au . The article was provided by the Backflow Prevention Association of Australia Incorporated. www.bpaa.org.au

A recent contamination event in New South Wales provided a lesson in backflow containment cross connections, contamination and leak detection.

Peter McLennan reports:

Backflow incidents happen more often than you probably think. But why do cross connections continue to happen when we have trained professionals working on our drinking water? Is it laziness, attention to detail or just plain ignorance?

The following happened in May 2021 and could have resulted in serious health issues for unsuspecting consumers.

The following happened in May 2021 and could have resulted in serious health issues for unsuspecting consumers.

A large New South Wales water utility recently experienced an unprecedented contamination event. Although no ongoing issues have been recorded, it highlights the potential for unrecognized contamination of the drinking water supply in both private on-site services and network infrastructure.

The contaminant: fluorescein, a brightly colored chemical product often used to identify leaks in sewers and rainwater systems. It is not made for use in drinking water as the following dictates:

Topical, oral and intravenous use of fluorescein can cause adverse reactions, including nausea, vomiting, hives, acute hypotension, anaphylaxis and related anaphylactoid reaction, causing cardiac arrest and sudden death due to anaphylactic shock.

The most common adverse reaction is nausea, due to a difference in the pH from the body and the pH of the sodium fluorescein dye; a number of other factors, however, are considered contributors as well. The nausea usually is transient and subsides quickly. Hives can range from a minor annoyance to severe, and a single dose of antihistamine may give complete relief. Anaphylactic shock and subsequent cardiac arrest and sudden death are very rare, but because they occur within minutes, a health-care provider who uses fluorescein should be prepared to perform emergency resuscitation. (Source: Wikipedia)

The investigation has identified two possible sources of contamination:

- Fluorescein may have been introduced to locate leaks in the newly installed fire service and interconnected pipework

- Uninstalled pipes and fittings may have been contaminated on site, during transport or a deliberate action

A new fire and domestic service was being installed in a public school, closed for the school holidays.

The fluorescein travelled through the new fire and domestic services into the existing domestic service, which had been cross connected for testing purposes.

The existing 40 mm water service and meter at the school did not have a backflow containment device in place, which allowed the fluorescein to travel into the network main, impacting several residential properties.

The existing 40 mm water service and meter at the school did not have a backflow containment device in place, which allowed the fluorescein to travel into the network main, impacting several residential properties.

Tap testing of the on-site outlets, which included drinking bubblers, produced large volumes of colored water; fortunately, it was a school holiday period.

This cross-connection event, if not for the presence of the fluorescein, may have gone undetected and highlights the need for due diligence when working on drinking water supplies.

The introduction of contaminants into any water supply could have fatal outcomes, as experienced with historical cross-connection events.

Our community has a reliance on licensed plumbers and on-site regulators to support quality plumbing installations and help protect the drinking water supply used by the community.

The unprecedented growth in the construction industry underscores the need for better regulation and compliance standards.

The safety of the drinking water supply should be of paramount importance whenever plumbing work is carried out.

Backflow prevention and cross-connection control is integral to keeping the drinking water safe and ensuring the health and amenity of the public.

Plumbers need to keep up to date on regulations and standards so a continuing professional development programme is introduced to cover aspects like backflow prevention as soon as possible.

For more information, please contact the Backflow Prevention Association of Australia Incorporated (BPAA).

NITC suppports the WPC’s objective to Create a Global Network

National Inspection Testing & Certification (NITC) is a full member organization and partner of the World Plumbing Council. As a third-party test administrator, NITC suppports the WPC’s objective to create a global network by offering individuals in the international plumbing community, at all levels of participiation and interest, a recognized measure of knowledge, skills and ability through third-party assessment.

NITC maintains a commitment to advance education and training in plumbing industries by offering high-quality examiniations for individuals. We certify installers, inspectors, instructors and verifiers throughout the plumbing industry, ensuring a qualified and accredited form of skill assessment is achieved.

In support of better design and governance of plumbing, NITC works with subject matter experts who perform a well-defined Job Task Analysis based on industry qualifications and code. This process allows NITC to develop an examination blueprint, offering a higher quality of product and service with a commitment to ensure properly trained individuals, working with properly trained instructors, enter the industry. Our plumbing certifications are recognized by the U.S. Department of Labor.

As part of the IWSH program, a charitable arm of The IAPMO Group, NITC participates in national and international projects, helping to improve water and sanitation for communities in need and contributing to the growth and development of the global plumbing industry.

How NITC participates with WPC in support of 4 Pillars

Participation: the training requirements to work in the industry

Not only does NITC participate in making certain only properly trained individuals enter and continue work within the industry, NITC relies upon guidance and tools provided by the American National Standards Institute to ensure our products and services consistently meet customers’ requirements, and quality is continually reviewed and improved upon.

NITC maintains an ISO 9001:2015 registration for our more frequently administered exams, ensuring that an independent third-party formally declares our certification programs are developed, maintained and administered in a way that facilitates:

- Exam Maintenance — with periodic review of exam and item performance;

- Quality Management — through a Quality Manual to ensure compliance with all policy and procedures related to certification; and

- Certification Maintenance — through recertification to established industry criteria.

NITC collaborates with the United Association, PIPE, ASSE, ASME, NFPA, ASHRAE, and Workcred, implementing strategies that foster participation regarding training within the plumbing industry.

Practices: standards and accountability in day-to-day work in the industry

NITC works in partnership with numerous established code and standard groups, such as IAPMO, through scientific research, debate, analysis and political awareness. ASME Section IX standards, recognized worldwide, serve as the basis for all NITC Brazer performance qualifications tests. NITC staff participates in Working Groups for standards development in the plumbing and piping industry, helping to ensure that current practices protect the quality and safety of day-to-day life. NITC, as a company, is committed to social responsibility throughout the world. Populations worldwide deserve the right to have safe drinking water and humane sanitary conditions.

Products: features and quality of the materials

NITC maintains ASSE’s Product Listing Program on its website. ASSE-certified products are tested by qualified laboratories to strict performance requirements of product standards, and certified in a manner that is impartial, balanced, informed, and rigorous. After 113 years of advocating for standardized plumbing practices and more than 50 years of certifying products, the ASSE Seal is proudly displayed on thousands of devices and assemblies throughout North America and referenced in the major U.S. model codes (UPC, IPC and NSPC).

Protection: measures to minimize risks and provide redress when failures occur.

NITC operates by rules and procedures, minimizing risk and providing redress for our product consumers. This offers examinees within the plumbing industry a swift, fair and impartial process by which to challenge and appeal any NITC exam item or procedure. This practice ensures exam integrity and quality and helps eliminate risk by certifying only qualified individuals to practice in the world plumbing community.

No More Waste: Plumbing Industry Launches PVC Recycling Scheme

As society moves its attention toward long-term sustainability, the Queensland plumbing industry has recognized its role in contributing to a responsible and sustainable future by diverting off-cuts of plastic pipes from landfills and recycling them into new pipes.

Master Plumbers’ Association Queensland (MPAQ) and Plastics Industry Pipe Association of Australia (PIPA), in conjunction with Iplex, Reece, Tradelink, and Vinidex, have joined forces to launch the Construction Plastics Recycling Scheme.

The Queensland government has provided funding support to ensure the delivery of the scheme’s six-month pilot program.

MPAQ Executive Director Penny Cornah said the Construction Plastics Recycling Scheme has been developed to help industry understand the volume of available PVC pipe off-cuts and fittings from construction sites.

“Our goal is to educate and change behaviors when it comes to the disposal of PVC off-cuts, which can be recycled into a new long-life recyclable pipe product,” Cornah said.

“This scheme highlights the environmental commitments of not only the partners involved but also the industry as a whole.”

The Construction Plastics Recycling Scheme officially began Nov. 1, 2021, with collection bins delivered to seven participating locations across South East Queensland, providing alternative outlets for PVC off-cuts to be discarded. The off-cuts collected in these bins during the scheme will be audited and data recorded.

Plastics Industry Pipe Association of Australia Executive General Manager Cindy Bray said most plastic pipes installed throughout Australia are 100% recyclable and can be easily reprocessed and manufactured into new pipe. Volume of plastic pipes in the waste stream are low due to their long service life, however waste, such as off-cuts generated during the installation process need to be captured and diverted from landfill. The Construction Plastics Recycling Scheme focuses on PVC non-pressure and pressure pipes and fittings.

“PVC pipe can be recycled six to seven times without significant reduction in pipe material quality requirements, highlighting the many benefits to collecting and recycling the off-cuts,” Bray said.

“Assuming a pipe lifetime of 100 years, the PVC material in PVC pipes may have a lifetime in excess of 600 years.”

Overall, the process of producing, recycling and reusing pipes has minimal environmental effects, highlighting the never-ending benefits of implementing the Construction Plastics Recycling Scheme.

Plastic pipes are smart, efficient and sustainable, providing long-lasting and reliable infrastructure both now and into the future.

Environment Minister Meaghan Scanlon said the Construction Plastics Recycling Scheme was a clear example of a “circular economy” in motion.

“As we move towards making Queensland a truly sustainable state operating on a circular economy – where waste is reduced and resources are recovered and re-used – initiatives such as the Construction Plastics Recycling Scheme can play a major role in achieving our goals,” Scanlon said.

An official launch event was held Nov. 12 at Reece Plumbing Supply Store in Labrador, with The Hon. Meaghan Scanlon MP, minister for the Environment and the Great Barrier Reef and minister for Science and Youth Affairs, attending the launch. For media inquiries, please see contacts below.

To find out more about the Construction Plastics Recycling Scheme and what can and cannot be recycled, visit www.mpaq.com.au/pvc.

Participating Partners

- Master Plumbers’ Association Queensland (MPAQ) – www.mpaq.com.au

- Plastics Industry Pipe Association of Australia (PIPA) – www.pipa.com.au

- Iplex – www.iplex.com.au

- Reece – www.reece.com.au

- Tradelink – www.tradelink.com.au

- Vinidex – www.vinidex.com.au

Participating Locations

- Beenleigh Plumbing Industry Climate Action Centre

- Caboolture Hospital

- The Star Casino Site Gold Coast

- Labrador Reece Plumbing Store

- Prominence Outlook Pallara

- Queen’s Wharf Brisbane Development (Towers 1 and 2)

- Woolloongabba Tradelink Store

New Zealand Institute of Central Heating Partners with BPEC to Raise Standards

Driving best practice through training: raising the standard for the installation of Hydronic Underfloor Heating in New Zealand

BPEC, the leading provider of training, qualifications and assessment services for plumbing, heating and gas, has worked with the New Zealand Institute of Central Heating (NZICH) on a new training scheme designed to raise standards. There is no current regulation on standards for hydronic heating in New Zealand for installers and end users to work to, and check against, to ensure the best possible systems are installed.

“Our mission is to improve the industry through best practice and training,” says Paul Woodgate, NZICH secretary. “Working with BPEC, we now have an accredited Underfloor Heating (UFH) Installer One course that will provide installers with a four-year accreditation. It also means we can approach architects and builders to develop greater knowledge and understanding of the right ways to design and install UFH.”

NZICH is a community of industry leaders providing technical information and experience, representing those responsible for the design, installation, commissioning and maintenance of central heating systems.

BPEC is a specialized UK-based provider of industry-recognized qualifications, assessments, training courses and learning materials, providing services to colleges, private training centers, employers and learners across the plumbing, heating, gas and wider energy sector.

“I had previous experience of BPEC as an installer and also instructing on UFH courses, so I knew BPEC had a training program we could adapt,” Woodgate said. “They provided UK manuals and presentations to develop the New Zealand version, which covers all the main points in terms of British standards while adding the features that are unique to how houses are built here. BPEC was flexible in the technical language, to reflect the differences in New Zealand while ensuring the training content remained rigorous. We can now be consistent in the terms used.”

NZICH recently completed a pilot program with eight candidates undergoing training and assessment.

“We were keen to work with NZICH and help raise the standards of hydronic heating installation in New Zealand, an approach that aligns with our values,” said Mally Butters, BPEC’s business area manager. “We are looking forward to developing our relationship — working together can only benefit NZICH and the sector in New Zealand by improving quality and skills.”

For more information on the New Zealand Institute of Central Heating, visit https://nzich.nz

For more information on this news release, email marketing@bpec.org.uk

DATES FOR DIARY

Plumb Skills Expo 2022

23 February – March 22, 2022

Virtual, India

plumbskillsexpo.com/

Kitchen and Bathroom Indonesia

23-26 March 2022

Jakarta International Expo Kemayoran, Jakarta – Indonesia

kitchenbathroomindonesia.com

DesignBUILD

10-12 May 2022

Melbourne Convention & Exhibition Centre

designbuildexpo.com.au

Emerging Water Technology Symposium (EWTS)

10-11 May 2022

San Antonio, Texas

ewts.org

PSCIA Inc. 34th ALBURY CONFERENCE – Supporting Plumbing Training

20-23 June 2022

pscia.org.au

IAPMO 93rd Annual Education and Business Conference

11 – 15 September 2022

Sheraton Charlotte

Charlotte, NC, USA

iapmo.org

WPC’s Conference 2022

13-15 October 2022

Shanghai Convention& Exhibition Center of International Sourcing

Shanghai, China

Contact secretariat@worldplumbing.org to provide an event report or request listing of an upcoming event.